In the fast-paced world of manufacturing, the seamless movement of materials is a cornerstone of efficiency and productivity. Different types of lifting equipment play a pivotal role in facilitating this process, offering industrial lifting solutions tailored to the unique needs of various industries. This blog serves as a comprehensive guide to understanding the diverse range of lifting equipment available and how they contribute to revolutionizing manufacturing processes.

1. Overhead Cranes:

Overhead cranes are workhorses in manufacturing, providing a versatile solution for lifting and moving heavy loads within a facility. With applications ranging from material handling in warehouses to precision tasks in manufacturing processes, overhead cranes offer robust functionality. Providers like Jagco excel in delivering advanced overhead crane solutions, ensuring efficiency and safety in the lifting and transporting of heavy materials.

2. Hoists:

Hoists are a fundamental component of lifting equipment, available in both manual and automated configurations. Manual hoists are ideal for smaller-scale applications, while automated hoists offer precision lifting in larger industrial settings. Jagco’s expertise in hoist solutions spans the spectrum, catering to the diverse needs of manufacturing operations.

3. Lift Tables:

Lift tables play a crucial role in ergonomic material handling, enabling the lifting and positioning of products and components. Designed with safety and efficiency in mind, lift tables contribute to a seamless workflow. Jagco’s tailored lift table solutions further enhance the efficiency of material handling processes in manufacturing.

4. Vacuum Lifters:

In industries where delicate materials or irregularly shaped items need to be handled with precision, vacuum lifters come into play. These lifters provide a secure grip without compromising the integrity of the materials being transported. Jagco’s innovative vacuum lifting solutions align with its commitment to delivering cutting-edge industrial lifting solutions.

5. Hydraulic Lifts:

Hydraulic lifts are widely employed for lifting heavy loads with precision and control. These lifts are known for their reliability in rigorous manufacturing environments. Jagco’s advanced hydraulic lift solutions contribute to the efficiency and safety of material handling processes.

6. Pneumatic Lifts:

Pneumatic lifts utilize compressed air to lift and move loads, offering a clean and efficient solution. This type of lifting equipment is particularly suitable for applications where precision and cleanliness are paramount, such as in the production of sensitive electronic components. Jagco’s pneumatic lift solutions exemplify innovation in meeting specific manufacturing requirements.

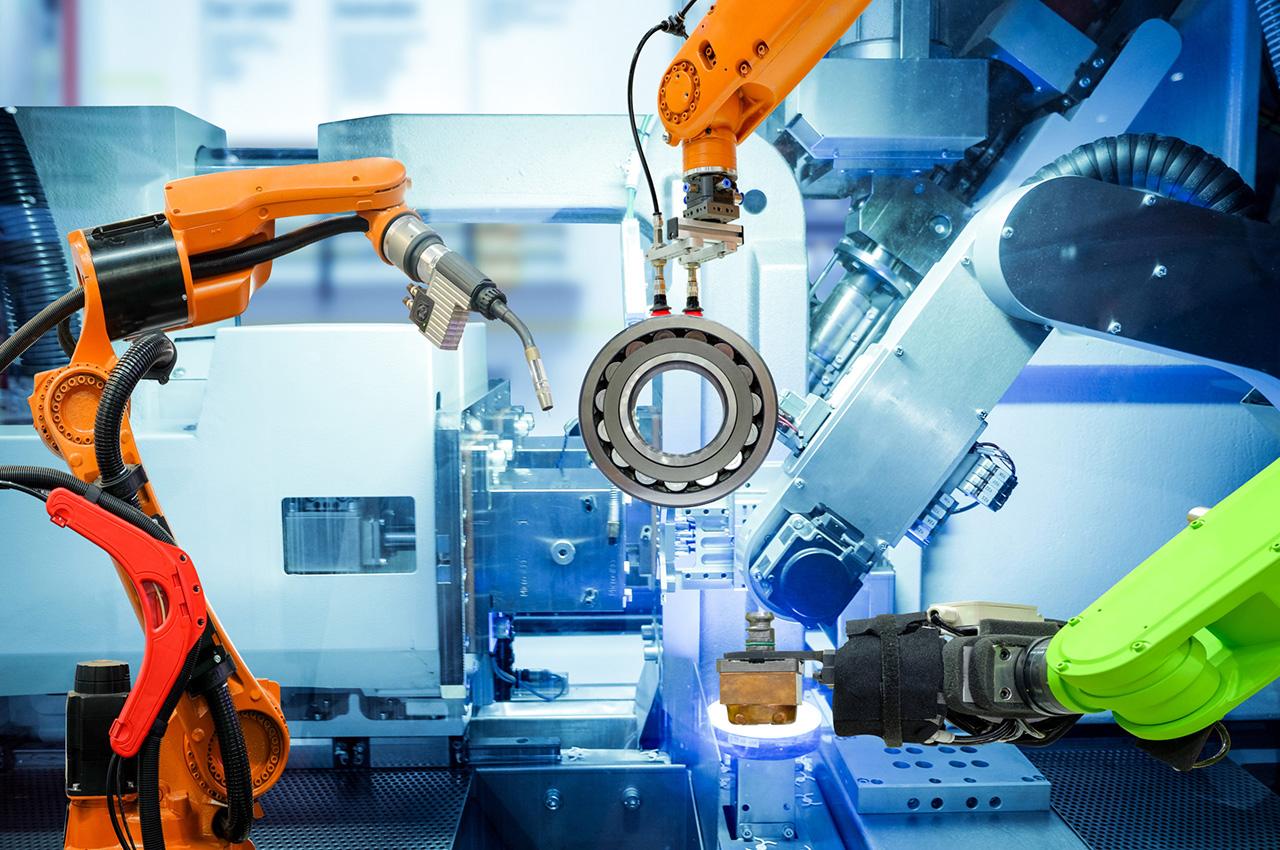

In conclusion, the world of lifting equipment in manufacturing is diverse and dynamic, with solutions tailored to meet the unique demands of each industry. As we navigate towards a smarter tomorrow, providers like Jagco play a crucial role in revolutionizing manufacturing processes by offering cutting-edge solutions that enhance efficiency, safety, and overall productivity. Jagco also provides advanced manufacturing solutions such as precision dispensing, automated fastening, lift assist, HMI & process monitoring, robotics, and vision systems to improve processes and increase efficiency. By understanding and implementing the right type of lifting equipment, industries can enhance their operations and embrace the transformative power of intelligent automation in material handling.