Fastener are essential components in construction, home improvement, and industrial projects. They are used to securely join materials, ensuring structural stability and functionality. This guide explores various types of fasteners, their classifications, and practical applications, providing insights for homeowners and building professionals alike – tokohasil.com.

Mechanical Fasteners

Mechanical fasteners create joints using physical force. They are widely used in construction and home applications due to their reliability and ease of installation.

1.1 Bolts and Nuts

Overview: Bolts are threaded rods paired with nuts to secure materials.

Applications: Structural framing, furniture assembly, and machinery connections.

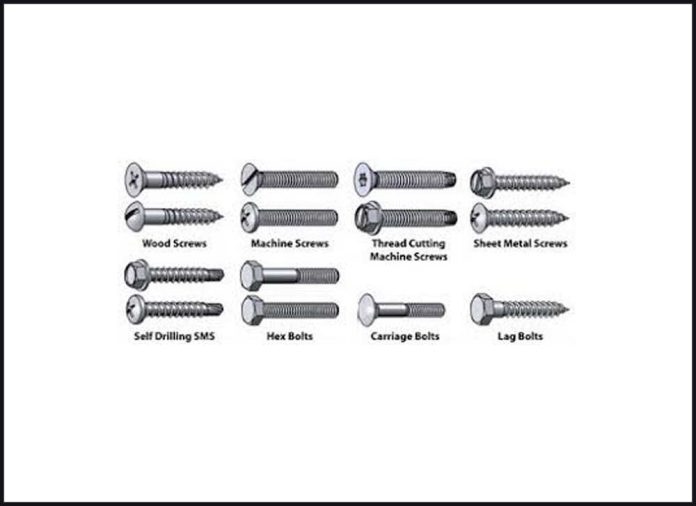

Variants: baut: Carriage bolts, hex bolts, and lag bolts.

1.2 Screws

Overview: Screws have helical threads designed to dig into materials for a firm grip.

Applications: Drywall installation, cabinetry, and decking.

Variants: Wood screws, sheet metal screws, and machine screws.

1.3 Nails

Overview: Nails are simple, smooth-shank fasteners driven into materials.

Applications: Framing, roofing, and flooring.

Variants: Common nails, finishing nails, and roofing nails.

1.4 Washers

Overview: Washers distribute the load of a fastener and prevent surface damage.

Applications: Used with bolts and screws to provide stability.

Variants: Flat washers, lock washers, and fender washers.

Adhesive Fasteners

Adhesive fasteners bond materials using chemical compounds, providing seamless joints without mechanical hardware.

2.1 Construction Adhesives

Overview: Strong adhesives designed for heavy-duty bonding.

Applications: Flooring, paneling, and wall-mounting.

2.2 Epoxy Resins

Overview: Durable, two-part adhesives offering high strength.

Applications: Bonding metal, glass, and wood surfaces.

2.3 Tapes and Strips

Overview: Double-sided tapes and adhesive strips for lightweight attachments.

Applications: Mounting decorative items, mirrors, and trims.

Specialty Fasteners

Specialty fasteners are designed for specific purposes or materials.

3.1 Anchors

Overview: Used to secure fasteners in materials like concrete or brick.

Applications: Hanging shelves, TV mounts, and fixtures.

Variants: Expansion anchors, sleeve anchors, and toggle bolts.

3.2 Rivets

Overview: Permanent fasteners used for non-removable joints.

Applications: Sheet metal assembly, automotive repairs, and aerospace structures.

Variants: Blind rivets, solid rivets, and tubular rivets.

3.3 Clips and Clamps

Overview: Provide temporary or semi-permanent fastening.

Applications: Securing hoses, cables, and piping.

- Variants: Spring clips, hose clamps, and retaining clips.

- Applications of Fasteners in Home and Building Projects

Fasteners play a vital role in various applications:

Home Improvement: Furniture assembly, shelving, and decor installation.

Building Construction: Framing, roofing, and plumbing systems.

DIY Projects: Crafting, gardening, and storage solutions.

Structural Installations: Securing beams, studs, and reinforcements.

- Tips for Choosing the Right Fasteners

- Material Compatibility: Ensure fasteners match the material type, such as wood, metal, or concrete.

- Load Requirements: Consider weight and stress factors to select suitable sizes and strengths.

- Environmental Resistance: Use corrosion-resistant fasteners for outdoor and humid environments.

- Ease of Installation: Choose user-friendly designs for quick and secure installation.

Conclusion

Understanding the types of fasteners and their applications helps homeowners and builders make informed choices for their projects. Whether for structural assembly or decorative installations, selecting the right fastener ensures safety, durability, and performance. Explore our wide range of fasteners to find the perfect fit for your next project!!