Edge position control is a critical aspect of modern manufacturing and processing systems where the precise management of material edges is essential. This article explores the fundamental concepts, technologies, and benefits of edge position control, as well as the latest innovations shaping its future.

Understanding Edge Position Control

Edge position control involves maintaining the accurate alignment of a material’s edge throughout various processing stages. This is vital for ensuring high-quality output, reducing waste, and optimizing production efficiency.

Key Objectives of Edge Position Control

- Precision Alignment: Achieve exact positioning of material edges to ensure consistency.

- Error Reduction: Minimize defects caused by misalignment.

- Efficiency Enhancement: Streamline operations to improve overall productivity.

Essential Components of Edge Position Control Systems

To effectively manage edge position, several key components work together:

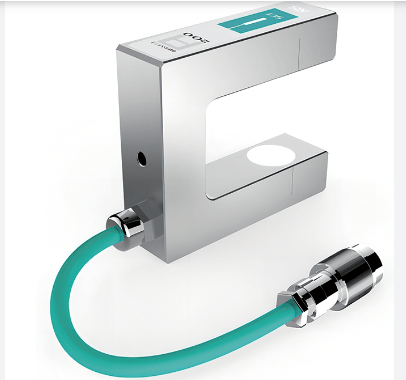

1. Sensors

Sensors play a crucial role in detecting and monitoring the edge of the material. Different types include:

- Laser Sensors: Utilize laser beams to measure edge distance with high precision.

- Optical Sensors: Employ light to detect edge position, suitable for various materials.

- Ultrasonic Sensors: Use sound waves to gauge edge position, ideal for non-contact measurements.

2. Controllers

Controllers process data from sensors and manage adjustments. They include:

- Microcontrollers: Handle real-time data processing and decision-making.

- Programmable Logic Controllers (PLCs): Offer robust control with programmable options for complex systems.

- Digital Signal Processors (DSPs): Specialize in processing high-speed data for precise control.

3. Actuators

Actuators implement changes based on controller commands. Types include:

- Electric Motors: Adjust mechanical components for precise alignment.

- Pneumatic Actuators: Utilize compressed air for flexible positioning.

- Hydraulic Actuators: Provide high-force adjustments for heavy-duty applications.

Advantages of Implementing Edge Position Control

Effective edge position control offers numerous benefits, including:

Enhanced Product Quality

Maintaining precise edge alignment ensures high-quality outputs, reducing the incidence of defects and inconsistencies in the final product.

Increased Production Efficiency

Automated edge position control systems streamline operations, allowing for higher production rates and reduced manual intervention.

Reduced Material Waste

By minimizing alignment errors, edge position control helps lower material waste, leading to cost savings and improved resource utilization.

Consistent Performance

Edge position control systems provide consistent performance across various manufacturing processes, enhancing overall reliability and reducing variations.

Applications of Edge Position Control

Edge position control is applied in various industries, each benefiting from precise material management:

1. Printing Industry

In printing, edge position control ensures accurate alignment of materials such as paper and film, leading to high-quality prints and reduced wastage.

2. Textile Manufacturing

For textiles, edge position control is crucial during processes like weaving and dyeing to maintain fabric alignment and achieve uniform quality.

3. Metal Processing

In metal processing, edge position control helps manage the alignment of sheets and strips during cutting and stamping operations, improving precision and reducing defects.

4. Packaging Industry

In packaging, maintaining proper edge alignment ensures that packaging materials are cut and assembled accurately, enhancing both functionality and aesthetics.

Innovations Driving Edge Position Control Forward

Recent advancements in technology have significantly enhanced edge position control systems:

Integration with Advanced Analytics

Modern systems use data analytics to monitor performance edge position control and predict adjustments, allowing for proactive management and optimization.

Integration with Industry 4.0

Edge position control systems are increasingly integrated with Industry 4.0 technologies, enabling smart manufacturing and improved data connectivity.

Enhanced Sensor Technology

Advancements in sensor technology provide higher resolution and faster response times, leading to more accurate and reliable edge position measurements.

AI and Machine Learning

Artificial intelligence and machine learning algorithms are used to optimize edge position control by analyzing large datasets and making real-time adjustments.

Future Trends in Edge Position Control

The future of edge position control is shaped by several emerging trends:

Increased Automation

The trend towards greater automation will drive the development of more sophisticated edge position control systems, reducing the need for manual adjustments.

Focus on Sustainability

Future edge position control technologies will emphasize energy efficiency and sustainability, aligning with broader environmental goals and reducing resource consumption.

Advanced Robotics Integration

Integration with robotics will enhance edge position control capabilities, providing greater precision and flexibility in handling various materials.

Evolution of Control Algorithms

Continued advancements in control algorithms will enable more sophisticated edge management strategies, accommodating increasingly complex manufacturing processes.

Conclusion

Edge position control is an essential aspect of modern manufacturing and processing, ensuring precise alignment of materials and enhancing overall production quality. With advancements in sensors, controllers, and actuators, as well as innovations driven by AI and Industry 4.0, edge position control systems are becoming increasingly sophisticated.

As technology continues to evolve, edge position control will benefit from greater automation, sustainability initiatives, and advanced analytics. Understanding and implementing effective edge position control strategies will be crucial for achieving high-quality, efficient, and reliable manufacturing processes.