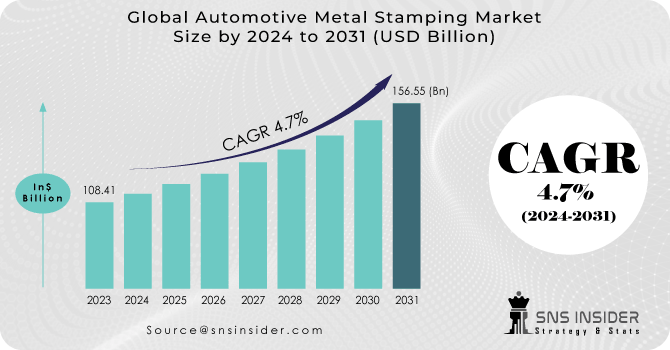

The Automotive Metal Stamping Market Forecast is poised for a remarkable transformation, driven by the rapidly evolving demands of the mobility industry and the need for innovative, lightweight, and high-performance components. According to a comprehensive market research report, the automotive metal stamping market size was valued at USD 108.41 billion in 2023 and is projected to reach a staggering USD 156.55 billion by 2031, exhibiting a robust compound annual growth rate (CAGR) of 4.7% during the forecast period of 2024-2031.

This substantial growth trajectory is fueled by a confluence of factors, including the increasing demand for fuel-efficient and electric vehicles, the adoption of advanced manufacturing technologies, and the growing emphasis on safety and performance in the automotive industry.

Get Free Sample PDF @ https://www.snsinsider.com/sample-request/1071

The Driving Force Behind Lightweight and High-Performance Components

Automotive metal stamping has long been a vital manufacturing process, enabling the production of precision-engineered components that are critical to vehicle structure, safety, and performance. As the automotive industry undergoes a transformative shift towards sustainable mobility solutions and enhanced safety standards, the demand for innovative metal stamping techniques and advanced materials has skyrocketed.

Through metal stamping processes such as blanking, coining, bending, embossing, and flanging, manufacturers can produce lightweight yet robust components that not only reduce vehicle weight and improve fuel efficiency but also meet stringent safety and performance requirements.

Market Segment Analysis

By Technology:

-Blanking

-Coining

-Bending

-Embossing

-Flanging

-Others

By Application:

-Passenger cars

-Commercial vehicles

-Recreational vehicles

By Process:

-Roll Forming

-Sheet Metal Forming

-Hot Stamping

-Metal Fabrication

-Others

The Electrification Revolution and Lightweight Design

The rapid rise of electric vehicles (EVs) has significantly disrupted the automotive industry, prompting a paradigm shift in component design and manufacturing processes. Lightweight construction is paramount in EVs, as it directly impacts range, performance, and overall efficiency. Automotive metal stamping plays a pivotal role in this context, enabling the production of lightweight yet strong components that contribute to the overall weight reduction of EVs.

By leveraging advanced materials and innovative metal stamping techniques, manufacturers can optimize component design, reduce material waste, and enhance structural integrity, ultimately delivering vehicles that offer superior range, performance, and sustainability.

Advanced Manufacturing Technologies and Industry 4.0

The automotive metal stamping market is at the forefront of embracing advanced manufacturing technologies and Industry 4.0 principles. The integration of smart manufacturing systems, automation, and digitalization has revolutionized the metal stamping process, enabling higher levels of precision, efficiency, and quality control.

From computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to advanced robotics and real-time process monitoring, these cutting-edge technologies are transforming the way metal stamping operations are conducted, ensuring consistent quality, reducing waste, and enhancing overall productivity.

The Role of Safety and Performance

As the automotive industry continues to prioritize safety and performance, the demand for high-quality, precision-engineered components has never been greater. Automotive metal stamping plays a critical role in producing components that meet stringent safety standards and performance requirements, such as structural components, brake components, and suspension systems.

Through advanced metal stamping techniques and the use of high-strength alloys, manufacturers can produce components that offer superior durability, impact resistance, and structural integrity, ensuring the safety of vehicle occupants and enhancing overall vehicle performance.

Regional Insights: Asia-Pacific Leads the Way

While the automotive metal stamping market is experiencing growth across all major regions, the Asia-Pacific region is emerging as a significant driving force. Countries like China, Japan, and India, with their thriving automotive manufacturing hubs and growing focus on sustainable mobility solutions, are propelling the demand for advanced metal stamping technologies and lightweight component designs.

The region’s commitment to reducing emissions and improving fuel efficiency, coupled with the presence of major automotive manufacturers and suppliers, is creating a fertile ground for the growth of the automotive metal stamping market.

Key Players and Strategic Initiatives

The automotive metal stamping market is highly competitive, with several key players vying for market share through strategic partnerships, acquisitions, and technological innovations. Prominent players in the market include:

-Aro Metal Stamping

-Alcoa Inc.

-Kenmode Precision Metal Stamping

-Interplex Industries

-Martinrea International

-Goshen Stamping Company

-Shiloh Industries Inc.

-Acro Metal Stamping

-Lindy Manufacturing

-Manor Tool & Manufacturing Company

-Tempco Manufacturing

-American Industrial Company

-Wisconsin Metal Parts Inc.

-Clow Stamping Co.

These industry leaders are actively investing in research and development efforts to introduce cutting-edge metal stamping technologies, expand their product portfolios, and explore strategic collaborations with automotive manufacturers, material suppliers, and technology providers to stay ahead of the curve.

For instance, in 2022, Gestamp Automoción announced a partnership with Volkswagen Group to develop innovative lightweighting solutions for electric vehicles, leveraging advanced metal stamping techniques and high-strength materials.

Regulatory Landscape and Challenges

While the automotive metal stamping market presents significant growth opportunities, it is not without its challenges. Ensuring compliance with stringent safety and environmental regulations, addressing concerns related to material sustainability and recycling, and managing the complexity of supply chain logistics are ongoing challenges that require careful navigation.

Additionally, the need for skilled labor and the potential impact of fluctuating raw material prices pose challenges that must be addressed by market players to maintain competitiveness and profitability.

However, the industry is actively collaborating with regulatory bodies and stakeholders to establish standardized guidelines and best practices, fostering a conducive environment for innovation while prioritizing sustainability and environmental responsibility.

The Future of Automotive Metal Stamping: Sustainable Materials and Digital Transformation

As the automotive industry continues its relentless march towards sustainable mobility, the future of the automotive metal stamping market is poised to embrace sustainable materials and digital transformation. The emphasis on reducing the environmental impact of manufacturing processes and promoting the use of recycled and eco-friendly materials will drive the development of innovative metal stamping solutions that align with circular economy principles.

Additionally, the integration of digital technologies, such as virtual reality (VR), augmented reality (AR), and advanced data analytics, will enable unprecedented levels of process optimization, predictive maintenance, and real-time quality control, further enhancing the efficiency and competitiveness of the automotive metal stamping industry.

In conclusion, the automotive metal stamping market is at the forefront of shaping the future of mobility, driven by the increasing demand for fuel-efficient and electric vehicles, the adoption of advanced manufacturing technologies, and the growing emphasis on safety and performance in the automotive industry. As the market continues to expand, key players are poised to capitalize on emerging trends, leveraging technological advancements, and introducing innovative solutions that cater to the evolving needs of automotive manufacturers worldwide.

Our Related Report

Automotive Smart Antenna Market Growth

Automotive Power Modules Market Growth